Flashing where Siding Meets Concrete (Helpful Steps)

Flashing where siding meets concrete. Welcome to the blog, where you can explore the art of flashing–the method of connecting pieces of siding to walls and other structures. Here, we’ll cover everything from common problems to creative solutions to ensure your siding won’t suffer from improper flashing. Let’s get started and show you how to make your siding shine!

Table of Contents

What is Flashing?

Flashing is a piece of material that is used during building and construction that prevents water leaks or drafts in areas where two materials meet. Flashing is typically made of metal, such as aluminum or galvanized steel. When placed properly over overlapping surfaces like roofing, siding, and concrete can create a barrier to protect the interior of a building.

The process of installing flashing is called flashing installation and should be done by a professional with experience. Proper flashing ensures the building materials’ longevity and helps prevent water intrusion damage. When installing flashing at places like where siding meets concrete, it should be placed so that it overlaps the siding on one side and extends beyond the edge of the concrete on the other side. This technique, along with sealed seams, will ensure proper waterproofing for your home or structure for many years to come.

Causes of Flashing Damage

Damage to the flashing where siding meets the concrete of a building is a common occurrence. Flashings are specialized pieces of metal that are installed to help redirect water away from spaces between certain parts of a building and can be found along with sidings, on roofs, and around windows or doors. It’s important to understand what can cause damage to this important protective layer so you can take the necessary steps for repair.

Common causes of flashing damage include:

- Poorly installed flashings that need to be correctly sealed between abutting surfaces.

- Aged or damaged caulking or sealant around flashings.

- Excessive exposure to wind can loosen fastenings and cause flashings to separate from framing members.

- Heavy moisture or snow buildup along the edge of the flashing may cause it to buckle or become dislodged from its framing connections if not properly secured in place.

- Incorrect sizing or position of fasteners used in installing flashings.

Flashing where Siding meets Concrete

When siding meets concrete, a waterproofing flash should be inserted in the joint. This will help to prevent damage from water seepage. The flash serves two purposes—one is to provide a seal between the surface of the concrete and the siding or wall cladding, and the other is to give an air space between them. This air space helps to vent out any moisture that may build up behind the siding and also helps protect against damage due to freezing temperatures.

Properly installed flashing should include a base, which is usually metal but may be plastic or rubber; corners along each side; a top piece, which fits over both sides at an angle; and finally, two sealants to secure it further. Before installing your flashing, check for any mold or mildew growth and get rid of it for your flashing installation to work properly.

Types of Flashing Available

Flashing is an often overlooked component of siding installations – but its importance in protecting your home cannot be overstated. Flashing helps keep moisture from seeping inside your home, and it’s especially vital where siding meets concrete, as this area is one of the most vulnerable parts of a house.

When selecting flashing material, you should consider the overall climate in your area and whether you’ll need additional protection against any weather pattern common to your region. Flashing can come in several different types, including copper, aluminum, galvanized steel, and more. Be sure to select a material that will have enough strength and durability for your local climate and moisture levels.

Types of Flashing Available:

- Aluminum: Aluminum flashing is lightweight and relatively inexpensive. It can also be shaped easily into different sizes and shapes as needed for installation around corners or other awkward spots in your house. However, it’s less durable in warmer climates or near coastal areas than some other metals or composite materials.

- Copper: Copper flashing has been used for centuries because it offers superior strength, flexibility, and corrosion resistance with very minimal upkeep requirements after installation compared to many other materials. It’s also more aesthetically pleasing than some other materials with its bright sheen that won’t require much maintenance throughout the years.

- Galvanized Steel: Galvanized steel is designed specifically to shield from moisture infiltration where siding meets concrete by providing an extra layer between the two materials that prevent water from seeping beneath them on contact. Galvanized steel flashing also requires minimal upkeep after installation; however, it’s important to consider that anti-corrosive sealants may also be necessary depending on climatic conditions at the time of construction/installation.

Which Siding needs Flashing

Flashing refers to installing materials that help form a waterproof barrier between two parts of a structure, such as where siding meets concrete. It is generally used in areas with frequent water exposure, helping protect the underlying material from moisture damage. Because siding is used on many types of buildings, there are several types of flashing used in different applications.

1. Wooden Siding

For wood siding, a wider flashing, such as a T shape, may be necessary for extra protection in order to bridge any gaps between the siding and concrete. A metal drip edge can also be installed at the bottom of the wooden siding, where it meets the concrete beneath it. This helps prevent water from seeping into the joints and damaging both surfaces.

2. Vinyl Siding

Vinyl is generally easier to install because it comes with its own flashing already attached at the bottom and along seams between pieces of vinyl. However, if you’re installing certain modified or thick siding types, you might need additional u-shaped flashes along angled pieces and edges near doors/windows.

3. Aluminum Siding

Aluminum siding must have gasket metal flashings installed when it meets downspout extensions or other metal components like gutters and fascia boards that run parallel to a wall’s surface. This way, water will follow those segmented paths instead of running down the wall behind the aluminum cladding.

4. Masonry or Concrete Sides

Where masonry or concrete panels meet each other at an angle (or in an L shape), through-wall flashings can be installed where two panels abut each other in order to keep liquids out and protect flashings from getting damaged by wind-driven rain (or snow drifts). Flashings may also seal up any irregular spaces on either side in order to ensure further water flows out correctly down into either panel’s lateral edges safely away from both surfaces involved.

Repairing Flashing around Concrete

When siding meets concrete, a moisture barrier should be installed to help protect the siding from potential water damage. This barrier is called flashing and is usually composed of metal or plastic pieces that are installed underneath the siding. Over time, these materials can deteriorate, resulting in problems such as moisture buildup and rot.

If you notice that your siding is not providing adequate protection against the elements, or if you suspect that there may be an unnecessary gap between your siding and concrete surface, then repairing flashing around the concrete may provide a solution to your moisture-related problems.

A thorough inspection should be done first in order to assess any visible damage or gaps. If gaps are present, they should be filled with caulk or other appropriate material depending on the type of surface involved and the situation at hand. The surrounding area should also be monitored in case further repairs need to take place afterward.

Once repairs are complete, new flashing must then be applied according to manufacturer instructions. Properly installed flashing will ensure that a secure seal is formed around all edges between the siding and the surrounding concrete surfaces. This will help prevent any future water infiltration, which could lead to more severe damage over time.

Steps to Prevent Future Flashings

Flashings are essential to your home’s exterior, as they provide a waterproof barrier between siding and concrete. If these flashings are not properly installed, this can lead to water damage in the future. Fortunately, there are some steps you can take to prevent future flashings from becoming a problem.

The most important step is making sure the flashing material is solid and free of holes or cracks. You should also ensure that the material is large enough to cover the entire width of the gap between siding and concrete. When installing your flashings, make sure to use heavy-duty nails or screws that won’t rust over time. Additionally, it would be best if you used caulking around all critical joints before nailing down your flashing for added protection.

Once your flashings have been installed, it’s important to inspect them on a regular basis for signs of weathering or wear. If any damage is spotted, it should be corrected as soon as possible to avoid more serious issues. Keeping an eye on where siding meets concrete will help ensure future flashing problems don’t develop in your home.

Tips for Installing your Flashing

Installing flashing is critical for seamlessly connecting your roof and wall system. This prevents water from entering the structure as it runs off the roof, down the siding, and into concrete. A proper installation of your flashing could result in costly damage due to water seepage. So, it’s important to make sure you get it right the first time.

The most commonly used type of flashing is aluminum step flashing, which is available in several different thicknesses and finishes to suit different budgets. The following tips will help you determine the correct type of aluminum step flashing needed for your project and ensure that it is correctly installed:

- Confirm measurements of where siding meets concrete.

- Determine your local building code requirements.

- Calculate how much material will be required for each step.

- Measure the length needed for the siding to run along each step.

- Perform any necessary cutting before you begin the installation.

- Make sure to leave an overlap in order to protect seams.

- Start at the bottom edge, and install up with tacks or screws every 6 inches.

- Install kick-out diverters as needed on all corners or bumps on walls.

- Caulk between siding and flashing using silicone caulk.

Choosing Appropriate Flashing

When it comes to flashing the junction between your siding and the concrete foundation of your home, there are several important considerations to keep in mind:

- Make sure that the flashing you choose is appropriate for your climate. If you live in a wet climate, you will need to choose a material that is resistant to moisture and won’t rust or corrode – aluminum or stainless steel are good choices in this case.

- Check that the flashing extends at least 6 inches up onto the siding and has adequate overlap with any adjacent areas, so water doesn’t seep through.

- Make sure that all of your fasteners are corrosion-resistant, so they don’t fail over time.

In addition to selecting appropriate materials for flashing where your siding meets concrete, be sure to hire an experienced contractor who understands how different materials react with each other and how much overlap is necessary for effective protection from water infiltration. Also, verify that any foam backings are appropriately placed behind siding and under flashing, as this additional defense is essential against water infiltration at these vulnerable areas of your home’s exterior.

In summary, be sure to take all of these measures before investing in new flashing for your siding-concrete junction—this way, you can ensure it will provide proper protection for many years to come!

Cost Considerations

When determining the cost of flashing where siding meets concrete, the materials and labor required should be taken into account. Different materials will require different amounts of time and effort to install. The materials chosen may also affect the level of maintenance they require, which can contribute to the overall cost.

Labor costs will depend on the complexity of the flashing installation project. If a professional installer is needed, their skill level and experience should factor into any cost considerations. Additional personnel may be required for complex jobs or if special tools are utilized.

The type of siding being used should also factor into cost considerations. Certain types and styles may require extra care or specialized treatment for proper installation, which could increase costs significantly. If heritage or other high-end siding is used, professional help from an experienced contractor may be necessary for optimal long-term performance and appearance.

Finally, all fixings utilized must meet local building regulations, which may also contribute to increased overall costs depending on state requirements or any specific permits that need accessing before beginning work on the project in question.

Flashing where Siding meets Brick

When your siding meets brick or masonry walls, the joints between them must be flashed to maintain a watertight seal between the two materials. Flashing these areas is relatively easy, but it requires attention to detail and understanding the principles at play.

For siding that meets brick, it’s important to make sure that there is no gap at the intersection before beginning installation. Start by installing a metal sill pan along the bottom of the siding, followed by flashing on both sides of the joint. The sill pan should have shingles embedded in it, which will help keep them from slipping out of place and make them easier to install.

Make sure that the flashing overlaps with both pieces of siding and that it seats firmly against all surfaces for maximum protection against moisture infiltration. Finally, run a bead of caulking along both lengths of vertical flashing perpendicular to each other where they meet in order to provide complete protection against water intrusion.

Flashing at the Bottom of the Siding

In order to prevent unwanted water infiltration and protect your home, it is important to construct an effective flashing system where your siding meets the concrete foundation. Flashings are the strongest waterproof barrier, specially designed to form a continuous seal between siding and foundations.

Flashings should be placed at both the top and bottom of each section of the siding, ensuring there are no gaps between panels or sidings. The bottom flashing should be installed first, with one edge sitting tight against the base of the sidewall. Measure carefully to ensure that enough flashing is used so that it extends at least 2-3 inches below the grade level of your home. For extra protection, consider adding another piece of metal flashing at this point, overlaying the previous piece before attaching both pieces with galvanized nails or caulk.

It is also important to ensure that all flashings are securely fastened along their length with galvanized nails or caulking to maximize their protective measures from water infiltration. This can often be done by using a slit cut in an L-shaped corner so it can be easily placed against two surfaces for added security. Additionally, for each section installed, check the entire perimeter for watertight integrity after completing each course of flashing installation – remembering to carefully inspect all seams and joints where two different surfaces intersect, as these areas tend to accumulate moisture more easily than others if not properly installed.

How to start vinyl siding on the concrete slab?

When installing vinyl siding on a concrete slab, one must first identify where the top of the siding panel should meet the concrete. Depending on the type and brand of vinyl, pieces may be cut with a utility knife or snip. The starter strip should be secured to the wall with screw nails every 16″ along its length to anchor it securely in place. After that is done, use a level to ensure that all of your panels align properly before nailing them in place with siding nails.

Once this is complete, insert additional siding nails at least 6″ apart along each panel. Nails should be punched slightly below the surface to prevent water from seeping into possible nail holes and slightly more than 1/8″ away from any previous nail holes. You’ll need to flash those areas at each end of the siding panels where they meet the concrete to prevent water infiltration problems.

You can achieve this by using flashing adhesive or even caulk, depending on your preference, and make sure it’s applied over both sides of the corner areas so that it seals out moisture without fail. Make sure also that any loose areas around windows or doors are properly sealed as well as around HVAC vents, for complete waterproofing protection for your new vinyl siding installation job.

How to install flashing on concrete wall?

Installing flashing on a concrete wall can be tricky if you need to know what you’re doing. Flashing prevents moisture, snow, and other materials from getting behind the siding and damaging the building. It also helps keep out pests and insects as well.

The first step in installing flashing is ensuring that your siding correctly meets the concrete wall. Measure across to guarantee that the ends of your siding line up with the edge of the concrete wall, then mark it for installation. Once your markings are in place, it is time to install your flashing material.

There are several types of flashing material available. Still, for this task, it is best to use a wide roll of aluminum or galvanized steel roofing flashing, which is specifically made for walls at home centers or online suppliers. When choosing your material, keep in mind that aluminum will rust over time when exposed to the weather, so galvanized steel may be preferred if you live in an area with harsh weather conditions year-round.

Cut the piece of flashing long enough to cover all edges where siding meets concrete leaving around an inch extra material on either side of each end, and use self-adhesive strips to secure it into place against the wall making sure there are no gaps or openings between pieces due to shrinkage or warping once applied onto a surface.

Then apply a liberal amount of waterproof silicone adhesive caulk around all edges before nailing any nails into place for extra security and finish off with a good layer of exterior paint on top of everything when satisfied with your work, ensuring that no exposed areas exist, leading moisture seepage underneath any materials used during this process!

Flashing Tape on Concrete

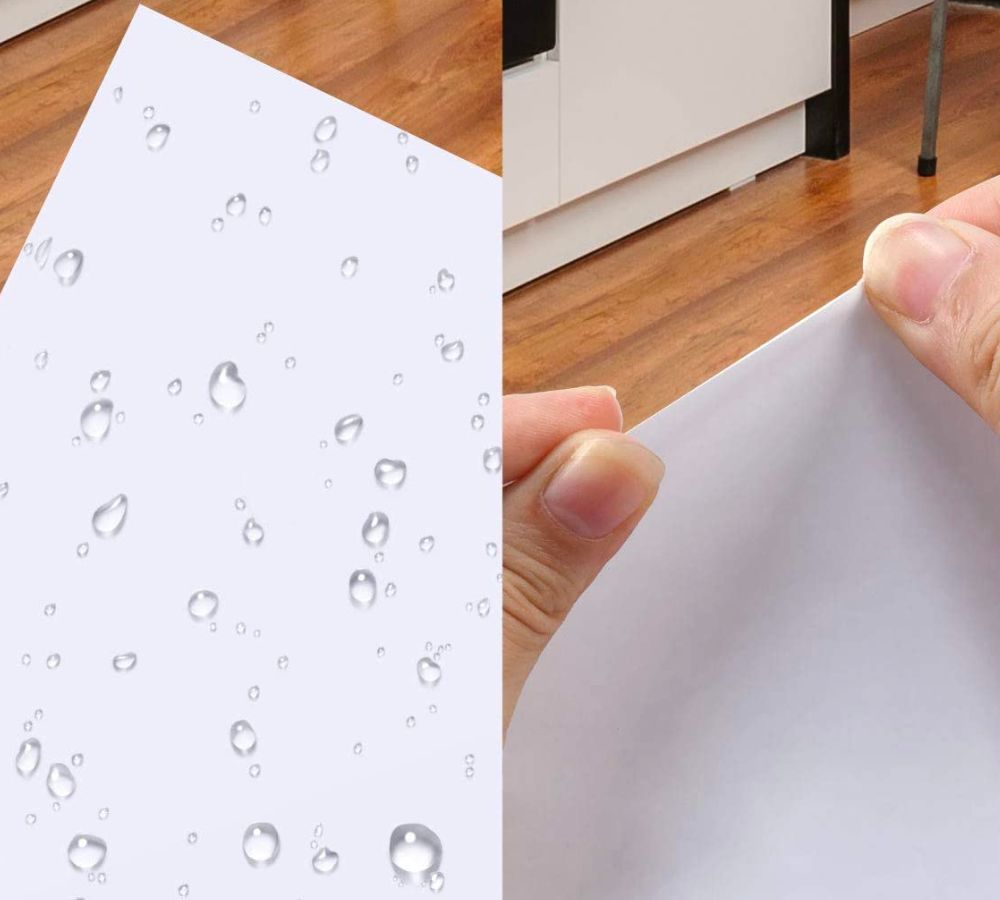

Before the siding is installed, a waterproof and flexible flashing tape should be placed around the perimeter of any concrete surfaces that will meet with the siding. This will help keep water from seeping into the gaps between the wood or vinyl siding and the surface of the concrete.

The tape should be pressed firmly against the surface of the concrete in long strips, allowing for minor overlap points as needed for a secure bond. If using multiple rolls of tape, each roll should overlap with its previous roll by several inches to provide maximum waterproofing coverage. It is important to use a tape designed specifically for use on concrete to ensure that it will not crack or fail over time due to temperature fluctuations or other wear and tear caused by exposure to the elements.

For best results, follow the manufacturer’s instructions when applying flashing tape on concrete.

Conclusion

In conclusion, flashing is an important factor in siding installation that should be noticed. Flashing protects against water leaks and potential structural damage. When done properly, it will provide a strong yet subtle connection between the siding and the concrete foundation beneath. Whether you’re a DIYer or a professional installer, mastering the art of flashing is essential to ensure that your siding project is completed with success.

To properly flash where your siding meets the concrete, you must use self-adhesive flashing tape designed for sealing around the edges. Start by cleaning the area where the siding meets the concrete with a cloth and a solution of mild detergent and water. Allow the surface to dry. Cut a piece of the flashing tape slightly larger than the area it will cover and press it firmly into place. Use a putty knife to smooth out any air bubbles or wrinkles.

You should use a self-adhesive flashing tape designed for sealing around the edges. It is important to choose a tape that is resistant to tears and water and can withstand outdoor elements.

With proper installation and care, the flashing tape should last for several years. It is important to check the tape periodically to ensure it is still adhering properly and has not been damaged by the outdoor elements.